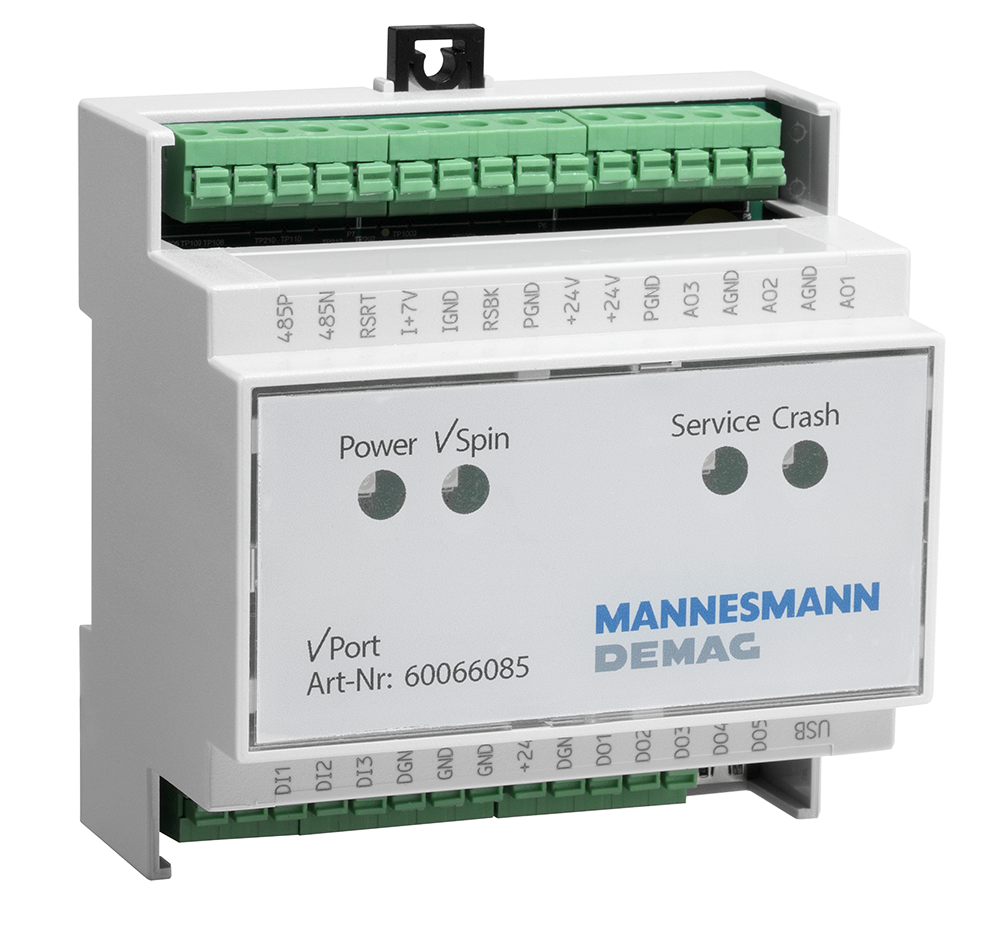

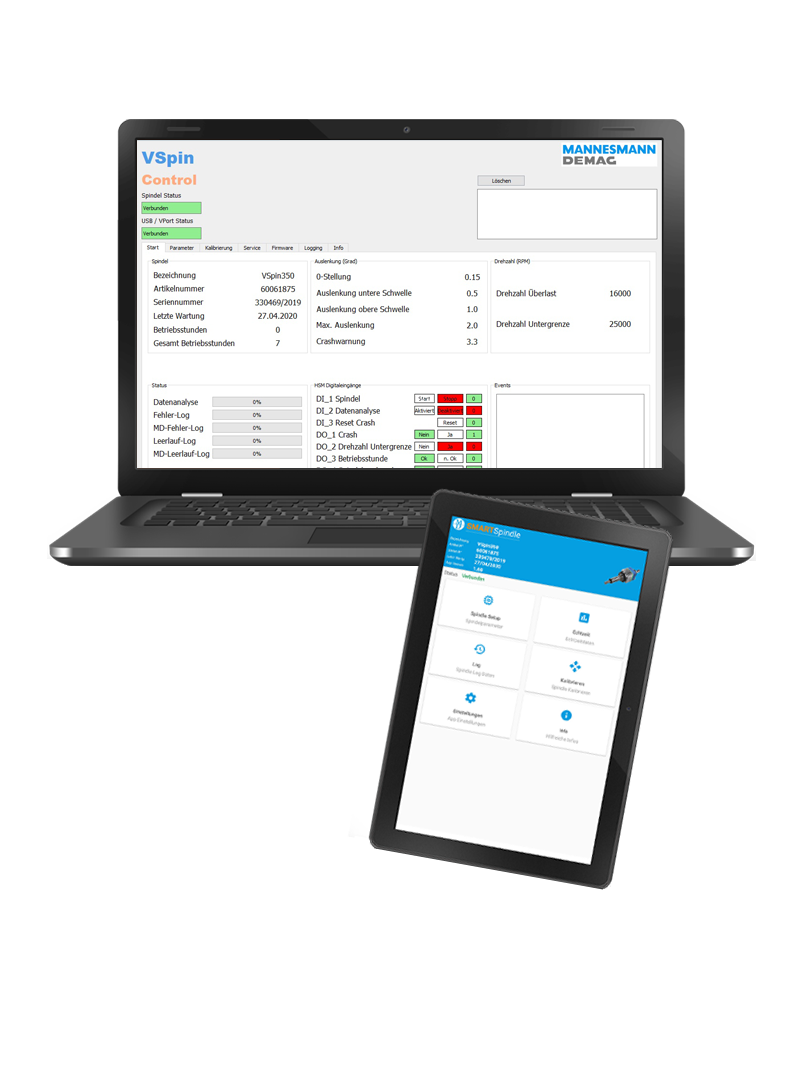

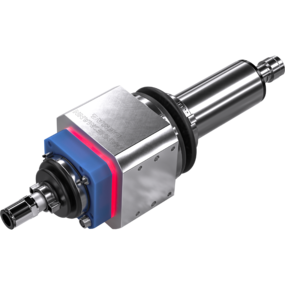

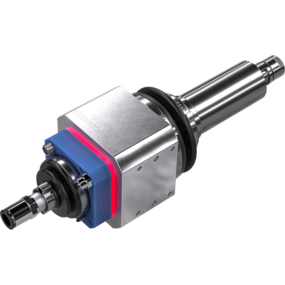

VPORT - THE INTERFACE TO THE ROBOT

The VPort has digital and analog interfaces for smooth integration of the deburring spindle into the existing control unit. When this data is integrated the robot can react to events such as the breakage of the milling cutter, a changed component contour or an excessive burr with an emergency stop or a tool change. By transmitting all process data of the spindle during the deburring process the full potential of the VSpin is realised.